Building Your Dream Backyard Shed: A DIY Guide

Hey there, fellow DIY enthusiasts! So, you're dreaming of a backyard shed â€" a glorious space for storing your gardening tools, bikes, or maybe even a secret crafting haven? Fantastic! Building your own shed might seem daunting, but trust me, it's totally achievable with a little planning and elbow grease. This guide will walk you through the basics, turning your shed dreams into a reality.

Planning Your Shed Project: Dream Big, But Start Small (ish)

Before you even think about grabbing a hammer, let's get the planning sorted. This is the crucial part, believe me! A little planning up front saves a whole lot of headaches later on.

Size and Location: The Golden Rules

First things first: how big do you need your shed to be? Consider what you'll be storing and how much space you realistically need. Remember to measure your yard carefully â€" you don't want your magnificent shed to be awkwardly crammed into a corner! Check your local building codes too; some areas have restrictions on shed size and placement. You might even need a permit, so do your homework!

Materials: Wood, Metal, or Plastic?

The shed material is a big decision. Wood offers a classic, customizable look but requires more maintenance. Metal sheds are durable and low-maintenance but can get hot in the summer and cold in the winter. Plastic sheds are the most budget-friendly and low-maintenance but are generally less sturdy and stylish. Weigh the pros and cons based on your needs and budget.

Tools of the Trade: Gather Your Arsenal

You'll need a range of tools for this project. Don't worry, you don't need a full-fledged workshop! Here's a basic list:

- Measuring tape

- Level

- Shovel

- Post-hole digger (or a strong friend!)

- Hammer

- Screwdriver (both Phillips and flathead)

- Circular saw (or hand saw for the truly ambitious)

- Drill

- Safety glasses

- Work gloves

You might need additional tools depending on the shed design and materials you choose. It's always better to have more than you need than to be caught short!

Building the Foundation: A Solid Start

A sturdy foundation is vital for a long-lasting shed. There are a few options here, each with its own pros and cons:

Concrete Slab: The Heavyweight Champion

This is the most robust option but also the most expensive and labor-intensive. It involves pouring a concrete slab, which requires some serious mixing and leveling skills. It’s best for larger or heavier sheds.

Gravel Base: A Budget-Friendly Friend

A gravel base is a simpler and more affordable option. You'll need to dig out a level area, lay down weed barrier fabric, and then add several inches of compacted gravel. This is suitable for smaller, lighter sheds.

Wooden Skids or Pressure-Treated Blocks: The Easy Route

This method is relatively quick and easy, making it ideal for smaller sheds. You simply place pressure-treated blocks or skids on the ground, ensuring they're level. This option isn't as durable as a concrete slab or gravel base, though.

Framing and Walls: The Shed's Skeleton

Once your foundation is set, it's time to build the frame. This usually involves creating a rectangular base using pressure-treated lumber, then erecting the walls. Follow your chosen shed plans meticulously, paying close attention to squareness and levelness. Remember, accuracy here is key to a stable and aesthetically pleasing shed.

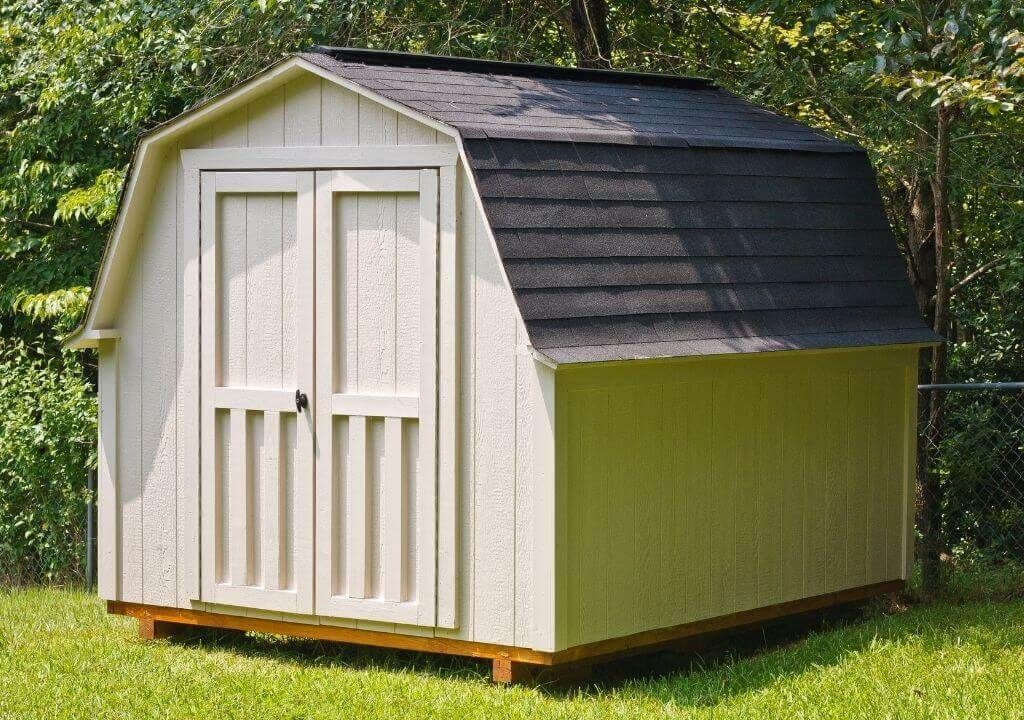

Roofing: Rain or Shine

The roof is the final piece of the puzzle. Common roofing materials for sheds include asphalt shingles, metal roofing, and even corrugated plastic sheets. Choose a material that suits your budget and aesthetic preferences. Make sure you have sufficient overhang to protect the walls from rain and snow. Proper sealing is essential to prevent leaks.

Finishing Touches: Doors, Windows, and Personalization

Once the structure is complete, you can add the finishing touches. This includes installing doors and windows, adding trim, and painting or staining the shed. Get creative here! This is your chance to personalize your shed and make it your own. Consider adding shelves, hooks, or other organizational features to maximize space and functionality.

Commonly Asked Questions

Q: How long does it take to build a backyard shed?

A: This depends on the size and complexity of your shed, as well as your experience level. A simple small shed might take a weekend, while a larger, more complex shed could take several weeks or even months.

Q: Do I need a building permit?

A: This varies by location. Check with your local authorities before you start building. Ignoring building codes can lead to serious fines.

Q: Can I build a shed myself, or should I hire a professional?

A: If you're handy with tools and have some DIY experience, building a shed yourself is totally doable. However, if you're not comfortable with construction, hiring a professional is always an option.

Q: How much does it cost to build a backyard shed?

A: The cost varies wildly depending on the size, materials, and features you choose. A simple small shed might cost a few hundred dollars, while a larger, more elaborate shed could cost thousands.

Q: What about insulation?

A: Insulation is optional but highly recommended if you plan to use your shed year-round or for temperature-sensitive items. Consider adding insulation to the walls and roof.

And there you have it! Building your own backyard shed can be a rewarding and satisfying experience. Remember to take your time, plan carefully, and most importantly, have fun! Happy building!